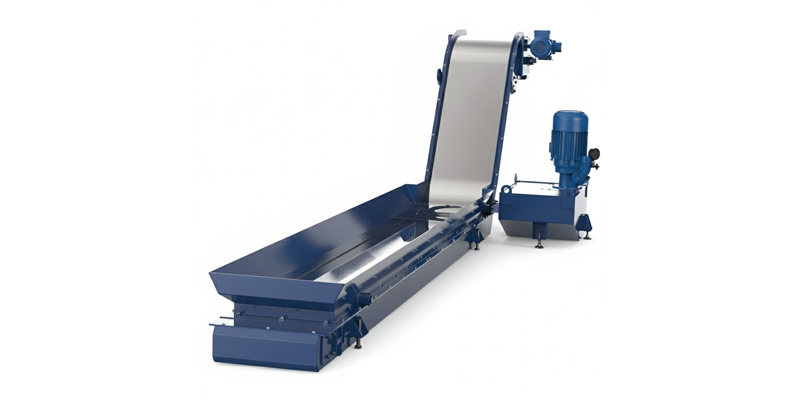

AECI Chip Conveyors are engineered for efficient and reliable handling of metal chips, swarf, and machining scrap generated from CNC and conventional machines. Designed with a robust, fully enclosed construction, these conveyors ensure smooth, continuous chip evacuation while preventing blockages and spillage. Their heavy-duty build and precision engineering help improve machine uptime, maintain a clean working environment, and reduce manual intervention.

Ideal for CNC machines, machining centers, transfer lines, and general-purpose machine tools. Suitable for conveying ferrous and non-ferrous chips, turnings, borings, and scrap in automotive, engineering, foundry, and manufacturing industries. Chip Conveyors can be customized for horizontal, inclined, or bend configurations based on machine layout and chip volume.

Efficient Chip & Scrap Handling

Heavy-Duty & Enclosed Construction

Reduces Machine Downtime

Improves Shop Floor Cleanliness

Custom-Built for Specific Applications

| Model | Conveyor Type | Chip Handling Capacity | Conveyor Length | Inclination | Belt / Mechanism | Drive System | Application |

|---|---|---|---|---|---|---|---|

| AECI-HBC | Hinged Belt Chip Conveyor | Up to 1000 kg/hr | Customized | Horizontal / Inclined | Steel Hinged Belt | Geared Motor | Heavy & Mixed Chips |

| AECI-MCC | Magnetic Chip Conveyor | Up to 800 kg/hr | Customized | Horizontal / Inclined | Permanent Magnetic System | Geared Motor | Ferrous Chips |

| AECI-SCC | Screw Chip Conveyor | Up to 500 kg/hr | Customized | Horizontal / Inclined | Helical Screw | Geared Motor | Fine & Powder Chips |

Our team is ready to help you design, customize, and optimize conveyor systems that improve productivity and reduce operational costs. Connect with us today.

Get a Free Consultation